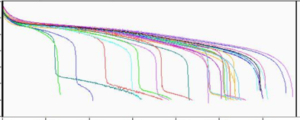

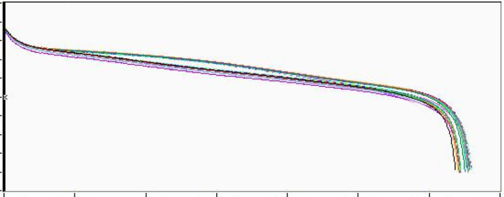

Before Reconditioning

- Each colored line represents an individual module (or cell) inside the failed hybrid battery.

- Lines of different lengths represent different capacities of the modules.

- Having many different length lines and especially many short lines means the battery was etremely out-of-balance with several bad modules.

What our equipment tells us

During Reconditioning

The reconditioning process is separated into several steps. These steps all use different equipment to achieve different goals.

- Cycling – Restores capacity and stress-tests the modules to eliminate weak modules or modules that may be nearing end of life.

- Profiling – Precision measurement of the modules is conducted to classify determine the important parameters of the modules.

- Final testing – Testing the final product under high load ensures that the reconditioning process results in a well balanced and matched hybrid battery pack.

What our equipment tells us

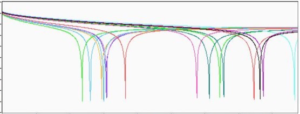

After Reconditioning

- After the reconditioning process every battery pack will consist of only high capacity modules with similar characteristics (Capacity, Resistance, etc).

- The graph shows all modules of similar high capacity which indicates a well balanced battery with matched modules.

What our equipment tells us